Laurini Officine Meccaniche among the key players at the 9th IBA biennial conference on international construction projects

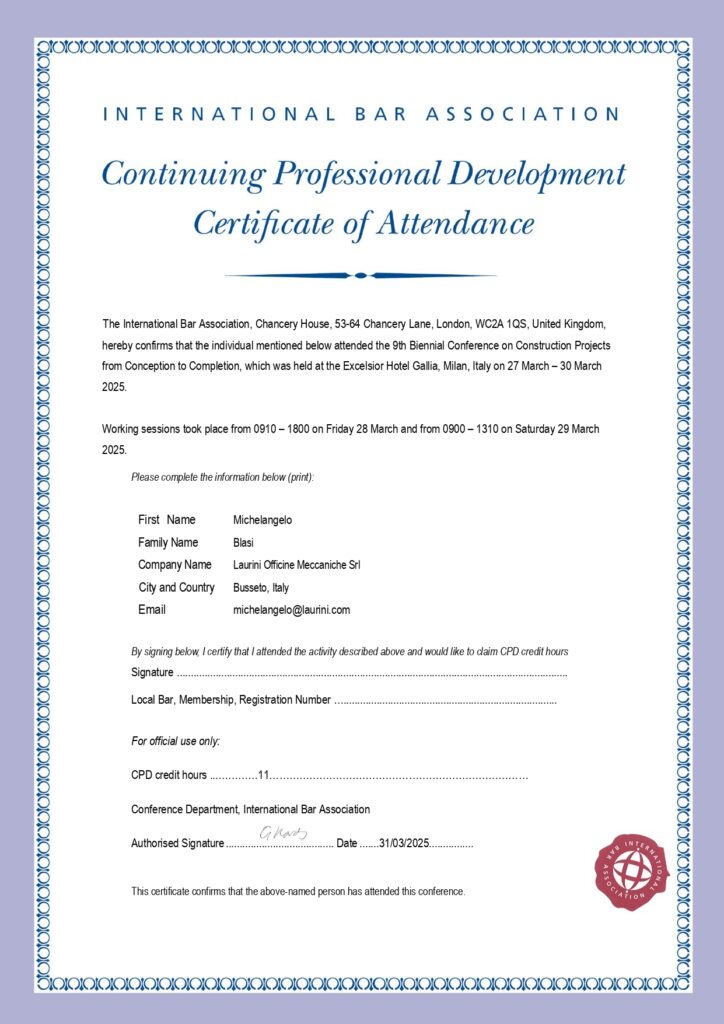

On March 28, 2025, the 9th edition of the biennial conference “Construction Projects from Conception to Completion”, promoted by the International Bar Association (IBA), took place in Milan at the Excelsior Hotel Gallia. This internationally significant event brought together legal, technical, and industrial experts to delve into the challenges and opportunities related to the execution of major infrastructure projects worldwide. During Session 4 – “The Use of New Technologies in Construction Projects”, Michelangelo Blasi, General Manager of Laurini Officine Meccaniche, delivered a presentation titled: “Laurini, The Game Changer”, focused on the engineering solutions developed by the company in strategic areas such as oil & gas, demolition, tunneling, and other energy infrastructures

Below is an excerpt from the presentation:

ADVANCED TECHNOLOGIES FOR COMPLEX CONSTRUCTION SITES: THE CONCRETE CONTRIBUTION OF LAURINI

The core of the presentation was an in-depth overview of some of the most innovative solutions designed and developed by Laurini, many of which were created in response to specific needs expressed directly by clients. Below is a summary of the most representative cases:

Pipeline – Production and management of backfill material

For pipeline construction sites in extreme environments (mountains, deserts, forests), where logistics and time are critical, Laurini developed a series of integrated machines that optimize bedding and backfilling operations:

• GRUB: a tracked crusher designed to work directly inside the trench, producing fine backfill material on-site.

• VULCANO 2.0: a radio-controlled mobile screener capable of generating up to 260 m³/h of selected material, drastically reducing internal transportation.

• HAMMER: a combined crushing and screening unit, equipped with a hammer mill for particularly rocky materials.

These machines represent an integrated system that reduces operational costs, improves site safety, and increases overall productivity.

Microtunneling – Tailor-made engineering for complex projects

In the microtunneling sector, Laurini contributed to major international projects such as the sea-to-land connection in Coatzacoalcos, Mexico, by providing:

• Custom sliding shoes (casing spacers), capable of simultaneously supporting the placement of three pipelines within the microtunnel.

• Structural calculations and FEM analysis, in collaboration with academic institutions, to certify loads and validate engineering standards.

• Destructive testing on components to ensure long-term strength and reliability.

This is a perfect example of integrated engineering involving universities, suppliers, test laboratories, and multidisciplinary internal teams.

Energy – Special projects for national infrastructure

In recent years, Laurini has contributed to strategic projects for national energy security, collaborating with SNAM on FSRU (Floating Storage Regasification Units) facilities:

• Piombino Project: design and implementation of a hydraulic system to test the strength of port bollards, with certified pulling force up to 300 tons.

• Ravenna Project: development of a mobile alignment system for installing offshore piles, capable of controlled movements along the X and Y axes, following satellite coordinates with high precision.

These projects demonstrate Laurini’s ability to tackle highly complex technical challenges while ensuring maximum reliability and safety.

Infrastructure – Automation in highway tunnel construction sites

One of the most innovative solutions presented was JOCKER, a fully automated system for milling tunnel vaults:

• Central positioning and continuous movement along the vault’s arc

• Remote control and automation of work cycles

• Adjustable-width frame for road transport

This solution significantly reduces work time, enhances operator safety, and decreases the number of machines required on-site.

Sustainable innovation through collaboration and training

In conclusion, Michelangelo Blasi emphasized two of the United Nations 2030 Agenda goals as fundamental for the sector’s future:

• Goal 4 – Quality Education: seen as training professionals capable of facing complex challenges with critical and creative thinking.

• Goal 17 – Partnerships for the Goals: because only through collaboration among different skill sets can real and sustainable progress be achieved.