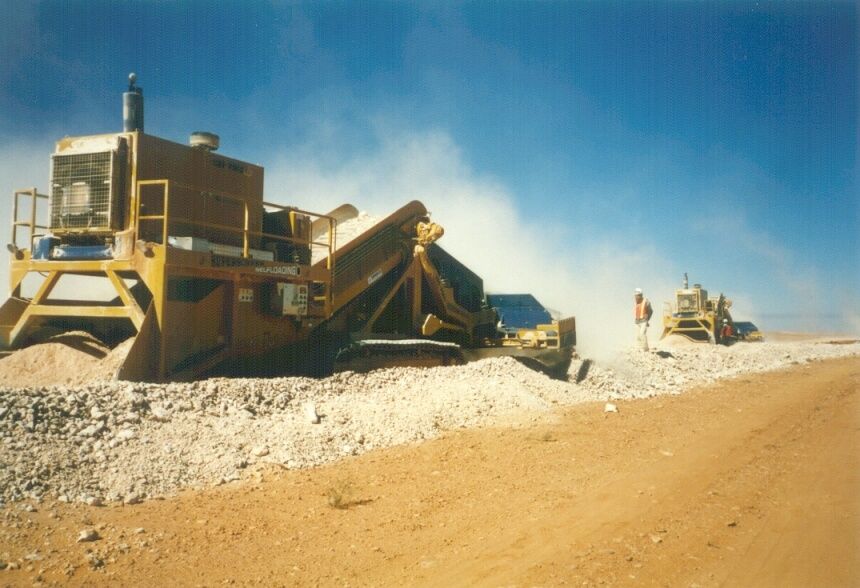

Selfloading Superscreen

Selfloading Superscreen

Our Innovative Solution for Self-Loading Screeners

Our Innovative Solution for Self-Loading Screeners

The Selfloading Superscreen represents a breakthrough in the field of self-loading screens. This advanced model, fully radio-controlled, is designed to ensure maximum productivity and reliability even in challenging operating conditions. With an impressive capacity of up to 280 m³/h, the Selfloading Superscreen is perfectly suited for large-scale projects such as daily underground pipeline construction, optimizing time and resources.

Efficiency and operational flexibility

Thanks to its innovative design, the Selfloading Superscreen is ideal for terrains with minimal morphological variations. Its retractable transverse conveyor belt with variable speed allows precise control of the amount of fine material conveyed into the trench, ensuring a uniform and well-distributed result. The radio control enables operators to work remotely in total safety, increasing precision and minimizing errors.

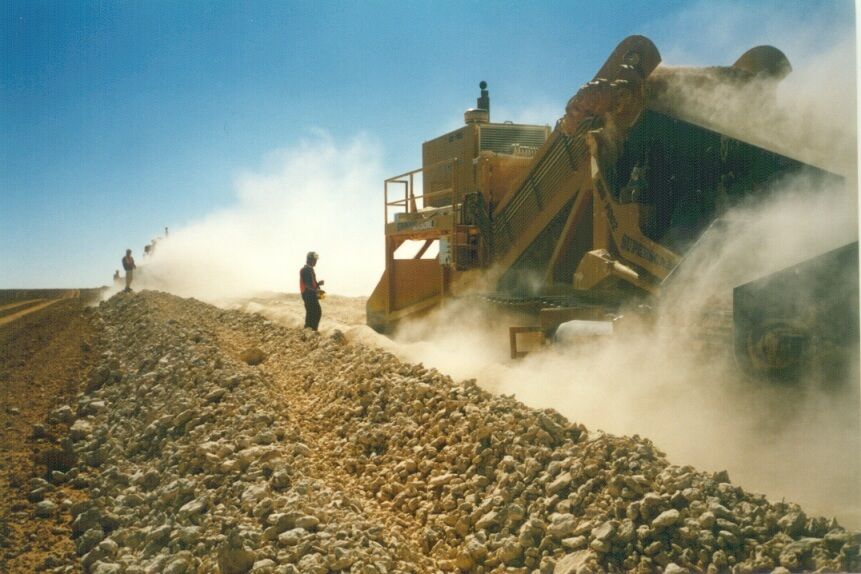

Advanced technology for a clean job

One of the standout features of the Selfloading Superscreen is the option to add a rear conveyor belt. This innovative system allows lateral separation of screening waste, leaving the ground perfectly clean and ready for further processing. This approach reduces cleaning times and enhances the overall efficiency of the process.

Precise adjustments for optimal results

The Selfloading Superscreen is equipped with a hydraulic deflector at the end of the conveyor belt, offering unprecedented control over the quantity and direction of fine material. This feature makes the machine particularly versatile, adapting to the specific needs of each project. Whether handling large volumes of material or working in confined spaces, the Selfloading Superscreen delivers excellent results in every context.

Benefits of batch processing

The innovative batch processing method allows multiple operations to be combined into a single, continuous workflow. The ground is screened, cleaned, and prepared in record time, reducing operational costs and increasing project completion speed. This solution is ideal for sites that demand high productivity and efficient organization.

Why choose the Selfloading Superscreen?

- High production capacity: up to 280 m³/h to handle large workloads.

- Operational versatility: suitable for various soil conditions with customizable configurations.

- Improved efficiency: waste separation and batch processing reduce operational time.

- Absolute precision: hydraulic deflector and adjustable speed for optimal control.

- Safety: remote control ensures safe operation from a distance.